Keycaps characteristics

Introduction

Keycaps are the face of a mechanical keyboard, the one you have chosen to give through a careful selection of colours, fonts, and shapes. Although often overlooked, those small caps have a great impact on the touch, acoustics and durability of your keyboard. They can be manufactured in many ways, which raises the following questions : what are the advantages and specificities of the differents marking methods? What about the various materials and multiple shapes? This guide aims to be an accessible introduction to help newcomers and new keyboard enthusiasts make an informed choice.

1. Material

Let’s start with the core of keycaps : what they are made of. Polymers (including plastics), metals, woods and ceramics – the list is quite long and so are their respective strenghts. In this guide, we will focus on the two most common plastics, that is, ABS and PBT.

ABS

ABS has two main advantages : it is affordable and easy to mold. This well known polymer has been used since the 1950s in various fields, such as the automobile industry, construction, medicine, packaging, 3D printing – and even in the toys of a well-known colorful-brick brand.

As a thermoplastic, ABS becomes soft at high temperature then hardens again when cooled down, allowing it to be reshaped several times. It offers great impact resistance and decent hardness at room temperature, all while keeping low processing temperatures, making it perfect for molding methods such as thermoforming or injection, which explains its popularity among industries.

When used in keycaps, ABS produces a clear, high pitched, crisp sound. It can be easily coloured by adding pigments before injection, giving a very saturated result.

Nonetheless, this material shows some weaknesses for this specific application – mainly regarding durability. It tends to age quickly with repeated finger contact causing the keycaps to develop a shiny, greasy appearance that can feel unpleasant. Exposition to UV rays through sunshine can also degrade the plastic over time, giving it a yellowish tint.

PBT

Unlike “standard” plastics, PBT could be called “technical”, as both its mechanical and thermal properties (including isolation and heat resistance) make it a most excellent choice for difficult environments. It is used in electrical, automotive, and aerospace industries — from circuit breakers and gears to pump housings and air ducts. It can even replace some metal parts. Its processing requires great care to avoid unwanted deformations, and slightly higher temperatures compared to ABS.

To produce keycaps, PBT can also be coloured by injecting pigments before molding, but offers another option as well : dye sublimation – a different printing method detailed later.

With a higher density, PBT produces a deeper signature sound compared to ABS. We exclusively use PBT in our keycaps because of its standout benefit: lasting physical and chemical resistance. This makes it ideal for preserving a matte surface finish over time.

Quick notes on acoustics and surface

While sound-signature is largely material-driven, the keycap’s thickness and geometry matters too. A well-crafted 1.5 mm thick ABS keycap will necessarily produce a lower sound than a 0.5mm thick PBT keycap. However, for equal thicknesses and identical shapes, PBT offers a deeper sound than ABS due to its porosity and higher density.

Surface texture is more about mold design than the material itself. A PBT keycap could be smooth and glossy, just like an ABS one could be textured and matte –it all depends on the mold’s surface roughness and the selected finish. To obtain a textured result, techniques like sandblasting or EDM (Electrical Discharge Machining) are usually done over the surfaces of the mould. That said, the material still influences the texture’s longevity : where ABS tends to become smooth relatively quickly, PBT is far more likely to retain its original appearance and matte texture over time.

2. Printing and Coloring Methods

Printing and coloring methods for keycaps are countless. For this guide, we’ll divide them into two categories : surface methods, and deep marking methods like double-shot and dye sublimation.

Surface Methods

By surface processes, we mean all the marking processes that are applied only on the surface of the key such as UV printing, pad printing, laser engraving, decalcomania or inkjet printing. Those are usually cheap to implement and very flexible. Nevertheless, they are not durable. If you have already seen a keyboard with fading legends, they must have been made using one of those methods.

Double shot molding

The concept is simple, though execution is not. A first injection is made to produce the keycap’s character, then a second injection completes it, adding the keycap’s body in the chosen colour around it. The interest of this method is its high consistency at a fast production pace. As the letter is made with the same thickness as the keycap itself, it will last even with an intensive use of the keyboard. Though this process can be used for both PBT and ABS, ABS remains better suited for it.

The downside ? It is expensive and lacks flexibility, thus increasing the set’s final price. Every keycap’s shape needs two molds plus a range of specific tools, and those must be adapted to every single design and linguistic layout ! Only the plastic colour can be changed without adapting the tools for each model, making this process ill-suited to our goal : supporting as many national European standards as possible.

Dye Sublimation

Dye sublimation is a very different method. The keycaps set’s design is printed onto a special film using sublimation inks. The film is then placed above the keycaps in a heat transfer oven. Once the target temperature is reached, the solid ink turns to gas and penetrates the plastic’s pores, then solidifies again as it cools down. This process is not only highly flexible but also delivers quality results close to double shot injection. Since the ink penetrates through a certain thickness of the surface itself, it will not wear off easily with time or use.

The range of achievable shades depends on the printer’s colour gamut – and since white ink doesn’t exist, we begin with blank white keycaps and add colour from there.

To cover all sides of a keycap in a single cycle, the plastic film is thermoformed around the cap using a vacuum pump which allows the pression required to be applied for the design transfer.

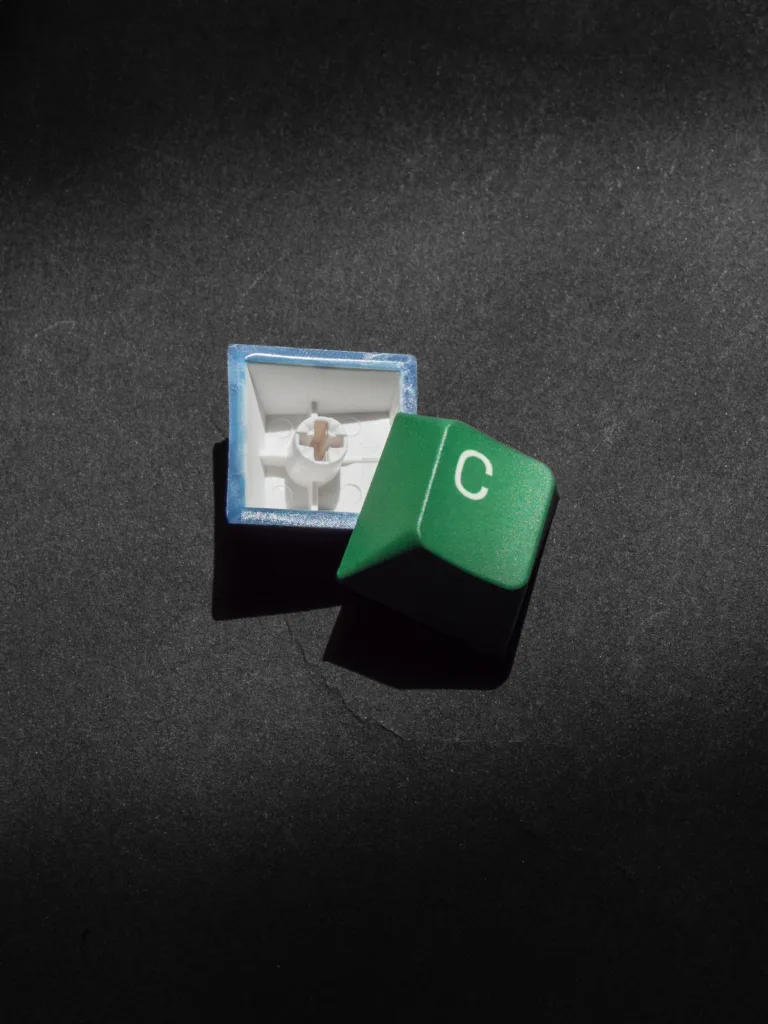

3. The MX mounting standard

While not the only standard, the MX stem mount is by far the most common. Introduced in 1983 by German company Cherry for their switch line, this cross-shaped mount is now ubiquitous in mechanical keyboards. Cherry switches are inexpensive, reliable, and have a satisfying typing feel — factors that explain their wide popularity.

If your keyboard uses MX-style switches, good news—you can use our keycaps!

4. Geometry and keycap profiles

Units

You may have come across keycaps sizes expressed in U units, where 1U = 19.05 mm. This is the ‘elementary’ unit used to define keyboard layouts – it measures the “influence” zone around the smallest keycaps. Basically, every 1U cap is usually around 18mm wide, leaving a 1.05mm space between each of them. From there we deduce the larger keycaps’ proportions, such as the tab key at 1.5U.

Any key 2U or larger typically requires the use of a stabilizer to ensure an even movement when pressed.

Profiles

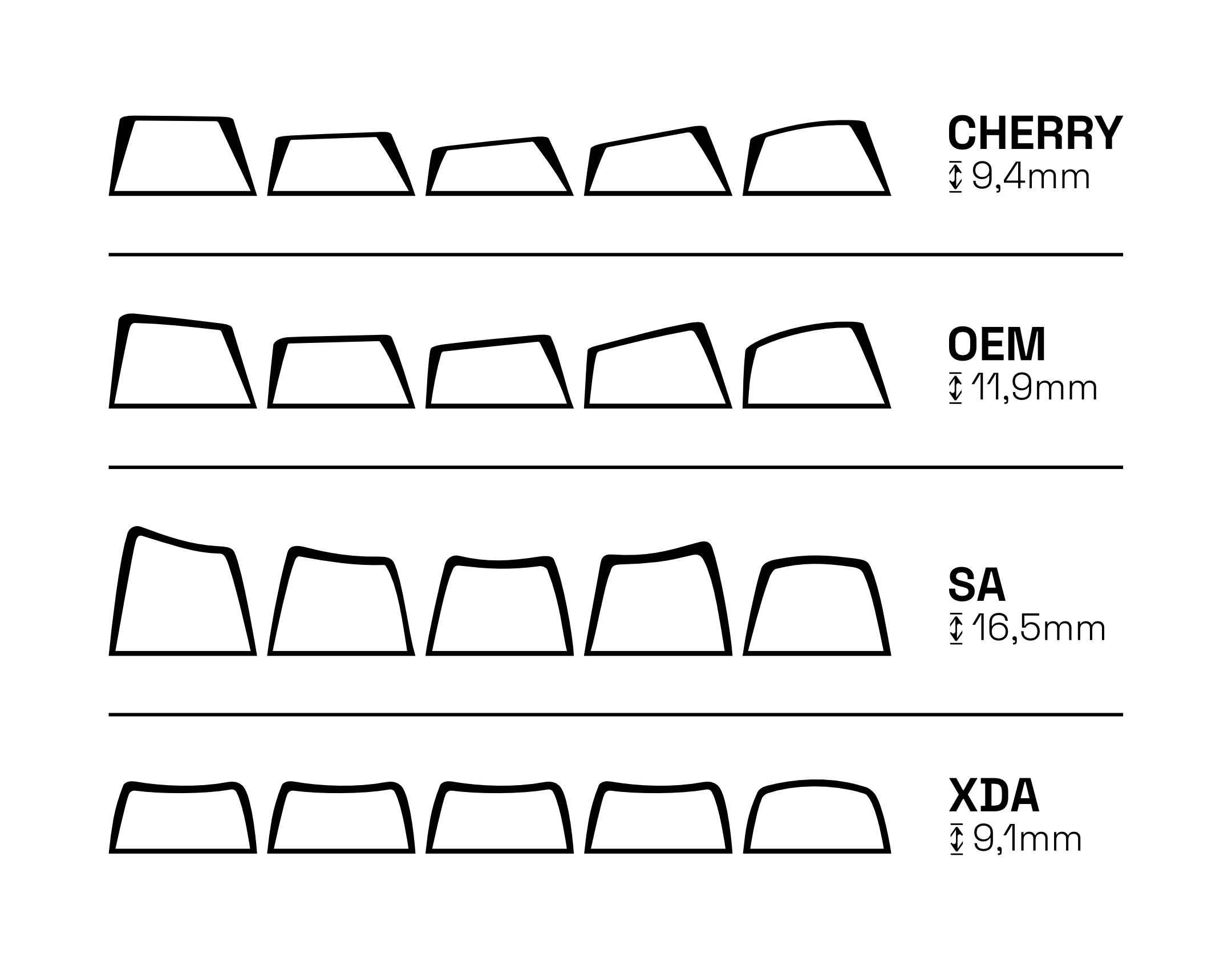

While the standard unit mentioned above is useful to design keycaps that are compatible with most keyboards, the keycaps’ aesthetics, shape and height are yet to be defined. This is where the profile steps in.

Dozens of them already exist but the most common profile is again called Cherry, designed by – you guessed it – Cherry. They are usually designed in 4 rows of keycaps with different shapes, labeled R1 to R4, meanwhile spacebars have their own convex geometry. Profile choice is mainly a matter of personal taste and typing comforts.

Here are a few examples :

Conclusion

Choosing the right keycaps is first and foremost a matter of personal taste. Nonetheless, it is important to keep in mind the technical trade-offs behind materials and manufacturing methods. We hope this short guide has answered most of your questions. If you are eager to learn more, or still have doubts about specific topics, check out our other guides for deeper insights !